研究開発、設計、製造、設置工事から品質管理まで自社一貫体制で、高品質なボイラシステムを提供します。

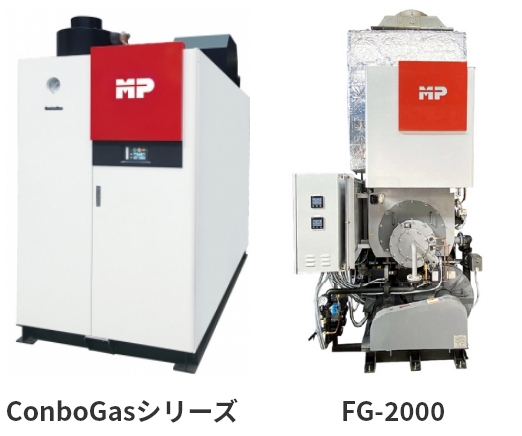

製品情報

製品一覧

製品検索

省エネ診断

ボイラーメーカーによる

最適ソリューションのご提案

- 省エネしたいが、方法が分からない

- 社内で省エネ推進しているが、外部の専門家に診てもらいたい

- 省エネの新技術や機器が知りたい

こんなときは、ヒラカワの省エネ診断をご利用ください。

工場でもビルでも業種・施設種類は問いません。